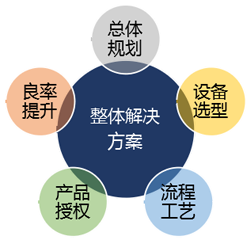

Integrated Solutions

North Ocean Photonics not only provides high-quality mass-produced products but also offers customized integrated solutions for clients with their own production and R&D needs. Through five key aspects—overall planning, equipment selection, process flow, product licensing, and yield improvement—we provide a complete closed-loop and one-stop solution. North Ocean Photonics commits to ensuring priority design support, fabrication support, and close R&D support for partner clients receiving our solutions.

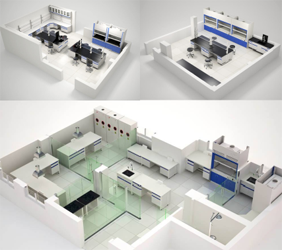

Overall Planning

Based on factors such as space, budget, products, applications, capacity, and pace, North Ocean can offer clients comprehensive planning for cleanroom environments, including overall layout, pipeline arrangements, and workstation setups, and can assist clients with inspection and acceptance. By implementing modular planning, we achieve optimal arrangements for modules like lithography, etching, fabrication, nanoimprinting, and packaging inspection, maximizing efficiency.

Equipment Selection

As an emerging frontier field, wafer-level optics equipment has significant customization requirements that must consider the compatibility of various stages of the production line with specific product processes. North Ocean Photonics has deep strategic partnerships with leading equipment manufacturers worldwide (including American, European, and Japanese firms). Based on client requirements, we can provide the most precise and suitable equipment selection and production line configuration. Through in-depth collaboration with partners, we can design specialized equipment and provide customized wafer-level optical equipment, offering high cost-performance options.

Process Flow

The production of wafer-level optics, especially in large-scale manufacturing, relies on optimal process flows that match the production line and products. North Ocean Photonics can provide a complete process flow tailored to client needs. We possess independent formulations and mixing plans for materials used in nanoimprinting and etching, enabling us to provide high cost-performance proprietary chemical materials based on product performance and price requirements.

Product Licensing

With extensive product experience, North Ocean Photonics has developed a series of wafer-level optical products, including diffractive optics, micro-lens arrays, optical waveguides, and optical communications. Relying on our complete foundry facilities, we have developed comprehensive process packages precisely tailored to each product. We are open to collaborating with clients through product and process licensing to assist them in achieving large-scale production. Several industry-leading large clients have already partnered with us through this approach. We can also conduct commissioned R&D or co-develop new products based on client needs.

Yield Improvement

The production and process team at North Ocean Photonics has extensive experience in large-scale semiconductor and optical production, familiar with systematic methods like lean management, Six Sigma, and yield improvement. After the production line is established, we can work with clients to systematically enhance yields and optimize the production line and processes. North Ocean Photonics has previously assisted a major client in improving the yield of their wafer-level optical production line by 20% within three months.